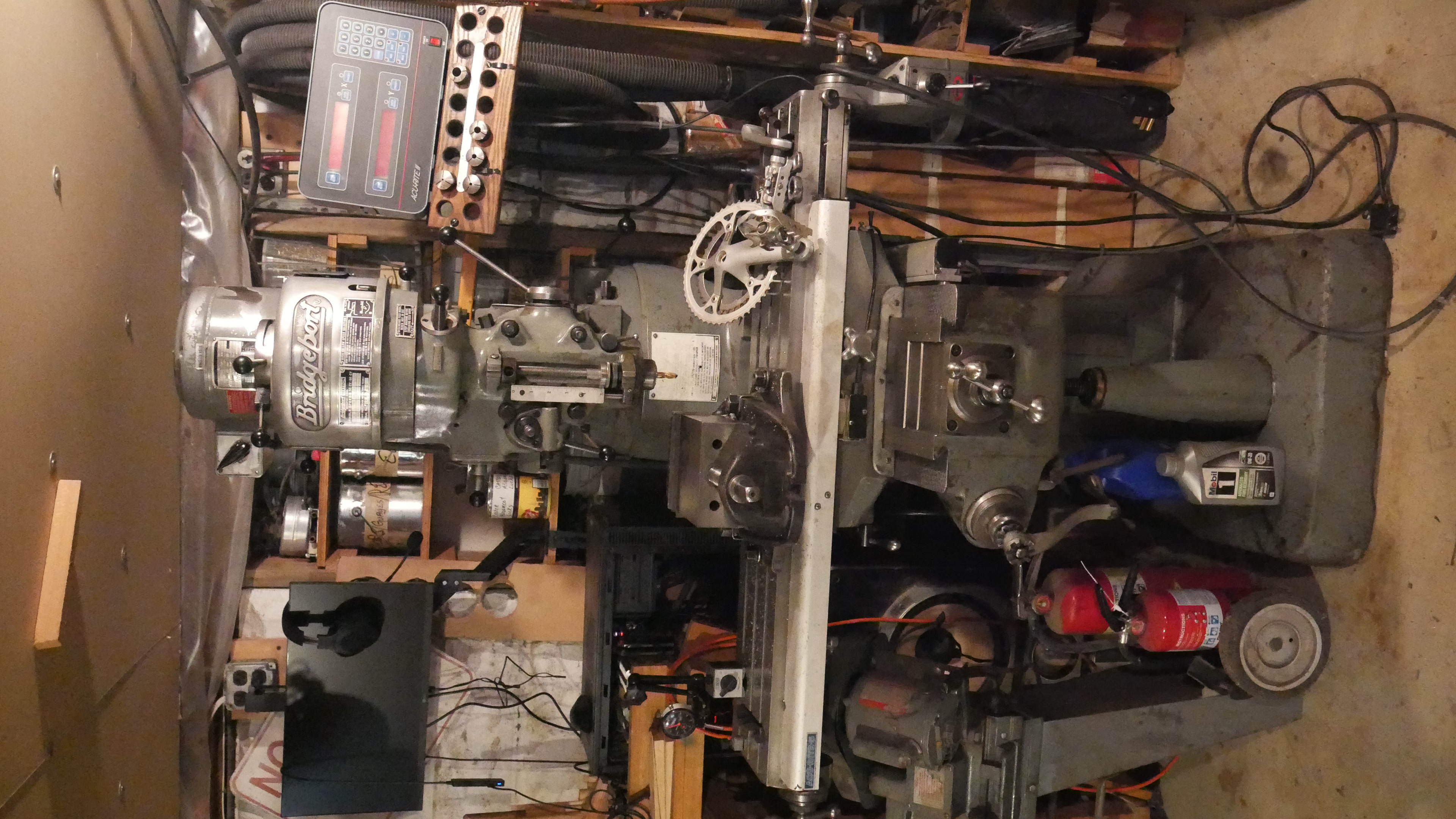

Bridgeport Milling Machine

Buying a used vertical milling machine

I have wanted to own a milling machine since the first time I had used one. This desire slowly grew until it was completely irresistable over the last year, which led me to start shopping around for machines.

I spent months pricing out used equipment and comparing the capabilities to new mini-mills. I was strongly considering purchasing a precision matthews milling machine but wasn’t sure it was the best choice.

Ideally, I was looking for the largest machine I could fit at a reasonable price. After looking around at specs of bridgeport machines I was convinced that they were too tall to fit in the shop space I had available. But, just to make sure I decided to go visit a machine reseller and measure some of the ones they had available.

I ended up finding a machine in exceptionally nice condition in the shortest configuration that was made (the 1 HP “pancake” motor).

The condition of the machine was incredible for being used. As you can see in the following images, the scraping was still on all the ways of the machine and the gibs (not shown) were hardly adjusted. In addition I brought a couple dial indicators and checked the spindle runout and backlash in the table.

At the price they were asking for the machine it was too hard for me to pass up.

So I bought the machine and paid for it to be delivered. The only problem now was actually getting it from my driveway into my basement. This short trip included traveling down a short grade and down a single step into my basement.

To get down the grade safely I decided to slowly walk (rotate one side at a time) the machine down. Obviously there are multiple ways I could have solved this problem, but this seemed like the safest at the time as this machine weighs a lot and is fairly expensive.

Once the machine was down the slope we put it on some small diameter pipes and rolled it to the door, down a small ramp, and into position.

The last hurdle to get over was providing the machine with power. These motors are wired for 3-phase 230V power, while most homes in the U.S. are only delivered 220V split phase. So to overcome this, I specced out an appropriately size variable frequency drive (VFD).

All wired up, the machine works!

There are still some things I plan on working on in the future:

Wiring up a control panel for the VFD

Making and enclosure for the VFD

A lot of tooling